|

Qingdao Shize Machinery Equipment Manufacture Co., Ltd.

|

wood plastic panel extrusion machine

| Price: | 150000.0~200000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

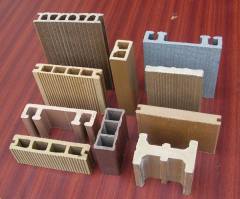

Wood plastic door machineThe product made by this line collects the advantages of wood and plastic.

Wood plastic panel making machine:

:

1, door material: WPC, PVC and wood composite

2, door size: 35-45mm thickness, 700-1000mm width

3, door type: Hollow inside, stronge wall

4, we provide turnkey project and best formula, Siemens conventer and Omron temperature control.

PVC WPC door panel making machine:

Wood plastic panel making machine is applicable to the continuous extruding of PVC door plate, clapboard 'elbow board and floorboard. Appropriate conical (parallel) double-screw extruder of different specifications should be chosen in accordance with different plate sections It is reasonably equipped with corresponding moulds vacuum calibrating table, caterpillar tractor, landscape orientation cutting machine, reversal stacker, etc.

Properties and Advantages:

1. Has compact structure, good plastification, high output, long life and other advantages. This line uses SJZ80 conical twin screw extruder or SJP90 parallel twib screw extruder with alternating-current inverter, imported electronic components and PT100 platinum resistance, which provide wide adjusting range and precise temperature control.

2. The down stream equipment includes vacuum calibration and cooling unit, haul-off unit, cutting machine and stacker.

3. The calibration unit is equiped with large forced cooling system so that it can probide perfect calibration effect.

4. The haul-off unit uses two line caterpillars. The lower one is fixed and the upper one can be adjusted according to the plate size.

5. The cutting machine is equiped with PLC control system which helps to set length and provide accurate automatic cutting.

6. The stacker is covered with rubber grip blocks to prevent products from damage.

2, door size: 35-45mm thickness, 700-1000mm width

3, door type: Hollow inside, stronge wall

4, we provide turnkey project and best formula, Siemens conventer and Omron temperature control.

PVC WPC door panel making machine:

Wood plastic panel making machine is applicable to the continuous extruding of PVC door plate, clapboard 'elbow board and floorboard. Appropriate conical (parallel) double-screw extruder of different specifications should be chosen in accordance with different plate sections It is reasonably equipped with corresponding moulds vacuum calibrating table, caterpillar tractor, landscape orientation cutting machine, reversal stacker, etc.

Properties and Advantages:

1. Has compact structure, good plastification, high output, long life and other advantages. This line uses SJZ80 conical twin screw extruder or SJP90 parallel twib screw extruder with alternating-current inverter, imported electronic components and PT100 platinum resistance, which provide wide adjusting range and precise temperature control.

2. The down stream equipment includes vacuum calibration and cooling unit, haul-off unit, cutting machine and stacker.

3. The calibration unit is equiped with large forced cooling system so that it can probide perfect calibration effect.

4. The haul-off unit uses two line caterpillars. The lower one is fixed and the upper one can be adjusted according to the plate size.

5. The cutting machine is equiped with PLC control system which helps to set length and provide accurate automatic cutting.

6. The stacker is covered with rubber grip blocks to prevent products from damage.

| 1 | conical twin screw extruder / SJSZ-92/188 | one set |

| 2 | Mold for door--1000*40mm | one set |

| 3 | Electronic Controlling system | One set |

| 4 | vacuum calibrating system / SZD-6000 | one set |

| 5 | Pair Roll Haul Off Machine / SLQ-1550 | one set |

| 6 | Transmitting machine / SXS-4000 | one set |

| 7 | Crosswise cutter / SQG-1000 | one set |

| Item | Parameter | |

| 1 | Processing Materials | PVC Powder + Wood Powder + Auxiliary Materials |

| 2 | Size of Extruded Door | 1220*2440*60mm |

| 3 | Extruding Speed | 0.5 -1.0 m/min |

| 4 | Max. Output Capacity | 500kg/h |

| 5 | Overall Size | 23, 000× 2, 500× 3, 000 mm L× W× H |

| 6 | N. W. | 16T |

| 7 | Total Installed Power | 300kw |

| 8 | Actual Energy Consumption | 210kw |

| 9 | Air Consumption | 0.4m3/min |

| 10 | Pressure | 0.6mpa |

| 11 | Water Cycle | 0.3m3/min |

| 12 | Working Condition | AC380V± 10%, 50HZ |

| 13 | Resource of Water | Industrial Water without impurities after filtration treatment. |

| 14 | Water Condition | 0.4 MPa ; 4-25 Celcius |

| 15 | Temperature of Working Condition | 0-40 Celcius |

| 16 | Max. width | 1220mm |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Wood Plastic Extrusion Line

Wood Plastic Extrusion

Wood Plastic Extrusion Machinery

Plastic Extrusion Machine

Extrusion Machine

Plastic Extrusion

More>>

.jpg)