|

Qingdao Shize Machinery Equipment Manufacture Co., Ltd.

|

Wood plastic board plant

| Price: | 40000.0~80000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

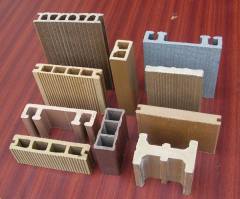

Wood plastic board extrusion machine adopt special design screw & barrel, die head and processing technique for wood-plastic products

1, board type: WPC, crust foam, hard and strong surface

2, board size: 1220*2440mm, thickness5-30mm

3, Usage: Furniture board, construction template

4, advantaghe: Stronge, enviroment freindly, can be resued for 50 times.

WPC board extrusion machine:

Adopting the Celuka structural-foam process technology, compared with the free foamed board, the skinning foamed board has the features of flattening and smooth surface, strong skinning hardness and stiffness, and better mechanical property.

The PVC WPC skinning foamed board extrusion machine is equipped with the conical double screw extruder, T-type plate mould, vacuum calibrating machine and ten-roller hauling off machine, etc; It will be widely used in many fields.

Application: High-grade cupboard, furniture, advertising materials, building decoration materials inner decorative materials for car, train and steamship. Decoration materials for car, train and steamship.

Properties and Advantages:

1, SJSZ92/188 WPC board extrusion line has compact structure, good plastification, high output, long life and other advantages. This line uses SJZ80 conical twin screw extruder or SJP90 parallel twib screw extruder with alternating-current inverter, imported electronic components and PT100 platinum resistance, which provide wide adjusting range and precise temperature control.

2, The down stream equipment includes vacuum calibration and cooling unit, haul-off unit, cutting machine and stacker.

3, The calibration unit is equiped with large forced cooling system so that it can probide perfect calibration effect.

4, The haul-off unit uses two line caterpillars. The lower one is fixed and the upper one can be adjusted according to the plate size.

5, The cutting machine is equiped with PLC control system which helps to set length and provide accurate automatic cutting.

6, The stacker is covered with rubber grip blocks to prevent products from damage.

2, board size: 1220*2440mm, thickness5-30mm

3, Usage: Furniture board, construction template

4, advantaghe: Stronge, enviroment freindly, can be resued for 50 times.

WPC board extrusion machine:

Adopting the Celuka structural-foam process technology, compared with the free foamed board, the skinning foamed board has the features of flattening and smooth surface, strong skinning hardness and stiffness, and better mechanical property.

The PVC WPC skinning foamed board extrusion machine is equipped with the conical double screw extruder, T-type plate mould, vacuum calibrating machine and ten-roller hauling off machine, etc; It will be widely used in many fields.

Application: High-grade cupboard, furniture, advertising materials, building decoration materials inner decorative materials for car, train and steamship. Decoration materials for car, train and steamship.

Properties and Advantages:

1, SJSZ92/188 WPC board extrusion line has compact structure, good plastification, high output, long life and other advantages. This line uses SJZ80 conical twin screw extruder or SJP90 parallel twib screw extruder with alternating-current inverter, imported electronic components and PT100 platinum resistance, which provide wide adjusting range and precise temperature control.

2, The down stream equipment includes vacuum calibration and cooling unit, haul-off unit, cutting machine and stacker.

3, The calibration unit is equiped with large forced cooling system so that it can probide perfect calibration effect.

4, The haul-off unit uses two line caterpillars. The lower one is fixed and the upper one can be adjusted according to the plate size.

5, The cutting machine is equiped with PLC control system which helps to set length and provide accurate automatic cutting.

6, The stacker is covered with rubber grip blocks to prevent products from damage.

| Machine | WPC board extrusion machine, celuka, crust foam |

| Raw material | PVC and wood composite |

| Application | Furniture board, construction template, formwork |

| Product size | 1220*2440mm, thickness: 5-20mm |

| Product density | generally 0.6ton/m3, can be customized 0.45-0.8 ton/m3 |

| Product features | hard and strong surface, long using life. |

| Machine model | SJSZ80/156 or SJSZ92/188 |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Wood Plastic Board

Wood Pellet Making Plant

Plastic Plant Pot

Plastic Plant Tray

Plastic Board

Wood Cutting Board

More>>