|

Qingdao Shize Machinery Equipment Manufacture Co., Ltd.

|

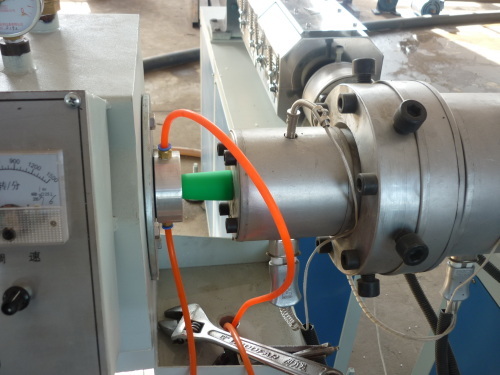

Plastic pipe making machine

| Price: | 30000.0~200000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to Basket | Add to My Favorites |

| HiSupplier Escrow |

Product Detail

This production line is used to made PPR PE water pipe.

Introduction of Plastic production line:

This production line is used to made PPR PE water pipe. The featrued of such pipe machine:

* Special single screw extruder for polyolefin, having high extruding velocity and effective plasticization

* Separation mixing screw specialized for polyolefin

* Specially designed three co-extruding die, reasonable channel, smooth outside and inside wall, and little internal stress

* Producing pipe φ 20-φ 630mm, manufacture velocity up to 16m/min

* May be used to produce HDPE silicon core, or ordinary PP-R, PE, and PEX pipes.

* Low cost: The cost of nanometer & anti-virus pipes is merely increase 5-10% on the ordinary pipe basis.

This production line is used to made PPR PE water pipe. The featrued of such pipe machine:

* Special single screw extruder for polyolefin, having high extruding velocity and effective plasticization

* Separation mixing screw specialized for polyolefin

* Specially designed three co-extruding die, reasonable channel, smooth outside and inside wall, and little internal stress

* Producing pipe φ 20-φ 630mm, manufacture velocity up to 16m/min

* May be used to produce HDPE silicon core, or ordinary PP-R, PE, and PEX pipes.

* Low cost: The cost of nanometer & anti-virus pipes is merely increase 5-10% on the ordinary pipe basis.

| Mode | PE75 | PE125 | PE250 | PE630 |

| (MM) Max Diam. | Φ75 | Φ125 | Φ250 | Φ630 |

| Extruder | SJ65/28--SJ65/30B | SJ90/28--SJ90/30B | SJ90/32---SJ90/32B | SJ120/30B |

| Power(KW) | 40/90 | 60/132 | 90/132 | 280 |

| Motor type | Direct current model | Direct current model | Direct current model | Direct current model |

| Output(KG/H) | 85/210 | 130/300 | 300/450 | 900-1000 |

| Speed(M/MIN) | 1.5-10 | 0.6-6 | 0.4-4 | 0.1-1 |

| Max.traction(N) | 9800 | 15000 | 19500 | 39000 |

| Cutting type | Disc type cutting | type cutting | Planet model with cut angle funcation | Planet model with cut angle funcation |

| Measurement(MM) | 28000×35000×3000 | 30000×35000×3000 | 38000×35000×3500 | 45000×35000×4000 |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Pipe Making Machine

Plastic Bag Making Machine

Plastic Cup Making Machine

Plastic Making Machine

Plastic Film Making Machine

Plastic Glove Making Machine

More>>

.jpg)